Findings on the Boiler Inspection of NC&St.L No. 576

Condition Is As or Better Than Expected; Repairs to Continue as Soon as Possible

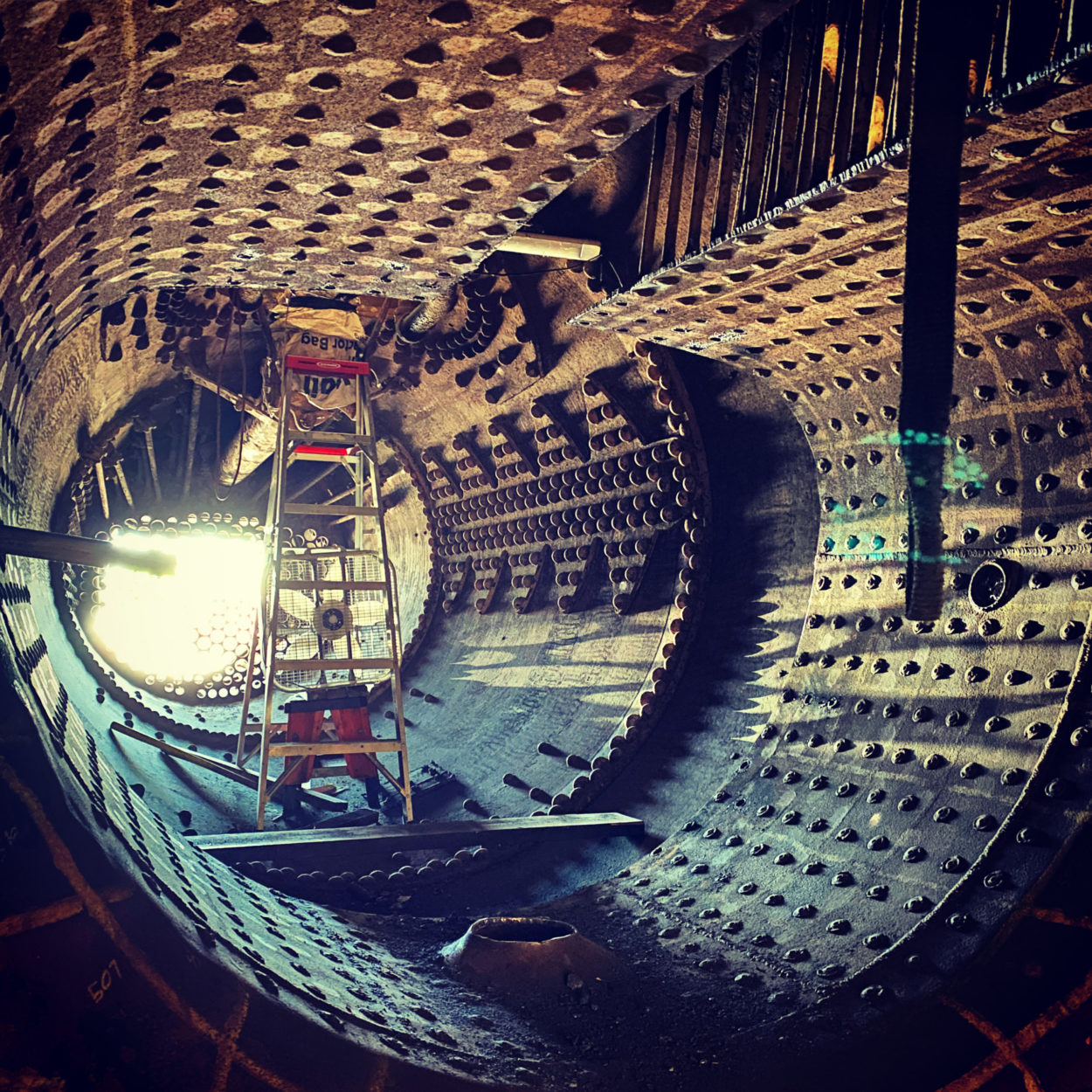

During the first few months of 2020, experts in steam mechanics and Nashville Steam volunteers inspected the current condition of No. 576’s boiler. Because of this cooperative effort, we have successfully identified all trouble areas of the boiler and have developed the scope of work for the boiler repairs. These efforts are already underway with volunteers logging, measuring, and removing nearly 70% of those “trouble” areas for repair and replacement prior to the temporary suspension of our mechanical work sessions. Our friends at World Testing, Inc. have provided their skill and resources that enabled the ultrasonic thickness (UT) testing to be completed, metallurgical analysis of all original boiler steel including calculating the tensile strength by using a hardness tester in conjunction with the metallurgy. All of this information is vital so that our engineers can accurately calculate the minimum thicknesses of each boiler plate, identify all trouble areas to address, and to ultimately ensure that the boiler is safe and suitable for service.

The repairs required to No. 576’s boiler will primarily focus on the areas surrounding and making up the firebox with the exception of some pad welding as allowed in 49 CFR 230 to the first boiler course due to corrosion from sitting on display in Centennial Park for 65 years. All work will be in accordance with 49 CFR 230, mandated by the Federal Railroad Administration (FRA), and will follow applicable railroad standard practices and the ASME and NBIC requirements.

The work that has been identified is as follows:

- Front tube sheet weld repairs to torch cut and nicked areas from its first tube replacement in 1947

- Pad welding corroded areas to the exterior of the first course.

- Replace a handful of rivets at the front course to tube sheet and butt strap seams due to heavy rivet head corrosion.

- Replace rear tube sheet due to unacceptable weld fit / high low at seam to combustion chamber and cracked tube and flue bridges. Rear tube sheet has been removed and material is ordered for the new one. Once on hand, the new sheet will be laid out, flanged, stress relieved, and all tube and flue holes cut into it with a water jet machine.

- Repairs to top rear combustion chamber syphon are necessary due to cracking. Combustion chamber syphon is removed and out for repairs.

- Both inside firebox side sheets will be replaced all the way to the mud ring due to excessively driven staybolt heads and thin lower portions of the sheets. Once time and effort were spent on welding up each staybolt hole to cut new threads, it was determined that it is cheaper and easier to replace the sheet when necessary to replace all of the staybolts in the area. Both inside side sheets are removed, all staybolts are removed, and sheet material is on order. Rivet heads were cut off to allow removal of the sheets. Rivets will be driven out next and replaced once the new sheet is installed and welded in.

- Wrapper sheet (outside firebox sheet) will require four flush patches, whereas the old sheets will be cut out, and new sheets formed, fit, and welded in to take the place of the original steel. These repairs are due to corrosion. Additionally, the top of the wrapper, sometimes referred too as the “roof sheet” will require some pad welding in areas that are marginal in thickness.

- The backhead will require three flush patches due to corrosion and some pad welding in a few other locations.

- Both inside rear corners of the firebox have been removed for replacement due to cracking.

- Both arch tubes have been removed and will both be replaced as this was a common component regularly replaced during the age of steam.

- Other repairs include replacing a large number of the boiler studs and flexible staybolt sleeves (and associated flexible staybolts) due to corrosion.

Major work on the boiler started in early March but was put on hold due to the COVID-19 pandemic. Material has been ordered for all sheet repairs and flexible staybolt sleeves and caps and we plan on getting back into high gear as soon as it is safe to do so.

It does look like a lot of work, and is, but it isn’t anything the experts involved with this project haven’t done before or can’t handle now. Keep in mind that the railroads commonly replaced many of these noted parts of the boiler that we shouldn’t have to change again for many years and will help ensure that No. 576 will be a reliable locomotive once restored and operating. The timing of this work to be completed is dependent on the availability of workers with the knowledge and expertise to conduct the needed repairs and consistent funding for the materials and contract work. We are very pleased with the condition of the boiler despite more than six decades of being exposed to the elements. The shop workers who prepped No. 576 for long term display clearly took pride in their work and ensuring the last remaining J-3 steam locomotive would be around for generations!