https://youtu.be/egNuRfQui30 NASHVILLE, Tennessee—The World War II-era steam locomotive currently under restoration after 65 years in…

Nashville SteamJuly 12, 2023

Nashville Steam Reaches Matching Fundraising Goal and Sets Record to Revive Music City’s Steam Engine…

Nashville SteamFebruary 21, 2022

Nashville Steam Successfully Lifts No. 576, Removes Wheels for Refurbishment Thanks to help from project…

Joey BryanJune 17, 2021

LEGENDARY STEAM LOCOMOTIVE’S RESTORATION HITS SIGNIFICANT MILESTONE WITH LIFT Two Cranes to Lift 220,000-Pound Historic…

Joey BryanJune 10, 2021

March 2021 Dear No. 576 Friends, The arrival of 2021 brings with it hope for…

Joey BryanMarch 4, 2021

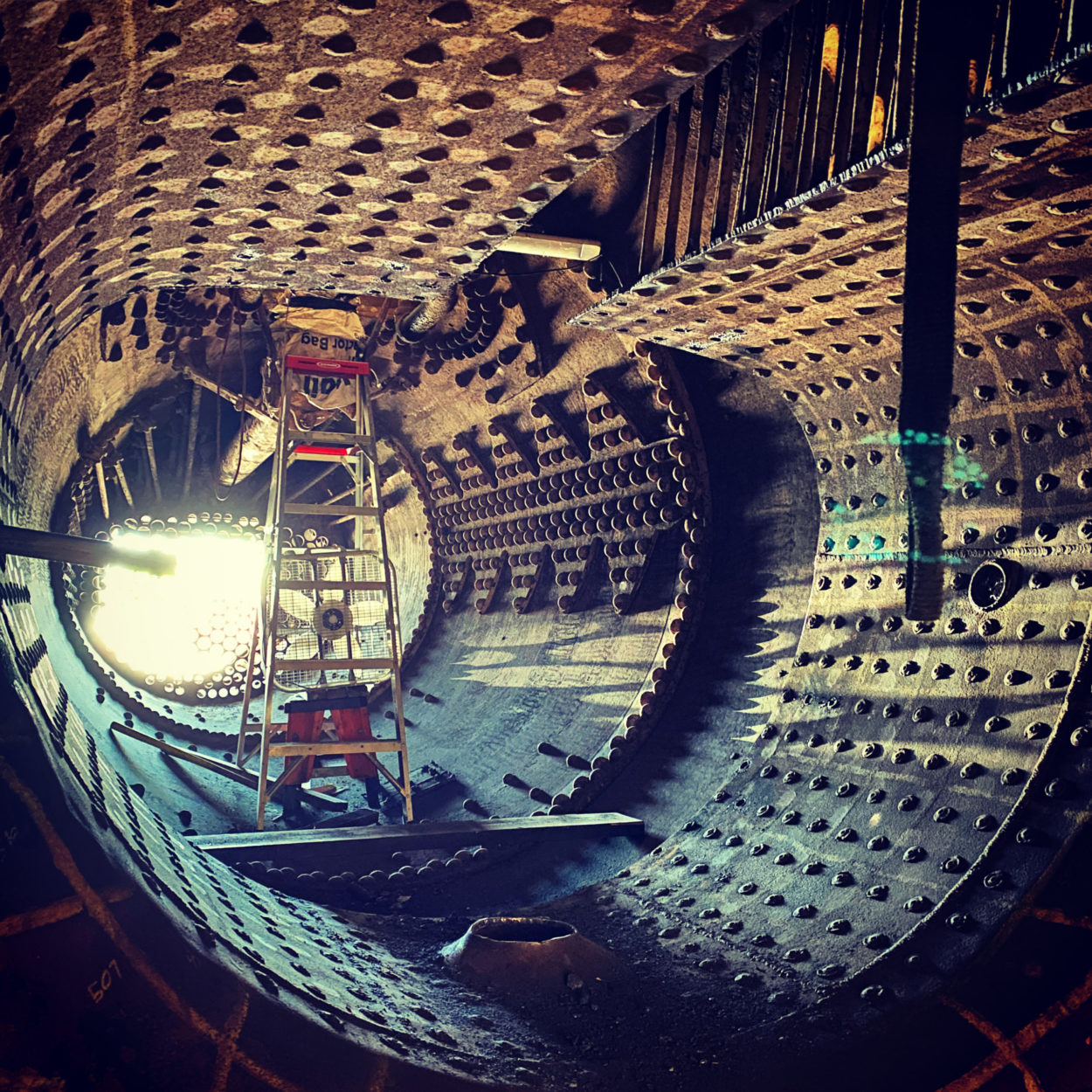

Findings on the Boiler Inspection of NC&St.L No. 576 Condition Is As or Better Than…

Joey BryanMay 3, 2020